Considerations for Cold Storage Roof Systems

Cold storage roofs represent extreme conditions that require special considerations for proper moisture management.

What are cold storage buildings?

Cold storage buildings are processing or holding facilities maintained at reduced interior temperatures. These buildings are broadly classified as large space coolers (>32ºF) or freezers (<32ºF). Examples of cold storage buildings include food processing plants, holding facilities for refrigerated or frozen foods, horticultural buildings, and warehousing for pharmaceutical products.

What are the risks?

Cold storage buildings create extreme temperature differentials between interior and exterior environments. This clash presents risks of condensation not typically seen with conventional roof systems. Related problems include corrosion, mold, material degradation, and reduced service life.

Condensation forms when air within or against building materials can no longer hold additional moisture at a given temperature – a condition referred to as the dew point temperature. Relative humidity is a way of expressing how much water vapor is actually in the air compared to how much it could hold at a specific temperature. Think of it like a sponge - a dry sponge can hold a lot more water than a wet sponge. Warm air can hold more water vapor than cold air. So, even if the amount of water vapor in the air stays the same, the relative humidity will be higher on a warm day than on a cold day.

Condensation arises from conditions governed by temperature. So, keep these fundamental concepts in mind when understanding associated risk to your cold storage roofing systems:

· Heat moves from warmer temperatures to cooler temperatures.

· Water vapor moves from high to low vapor pressure.

· Air moves from high pressure to low pressure.

Understanding Thermal and Vapor Gradients in Cold Storage Roofs

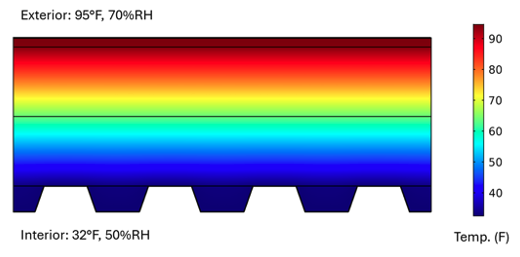

By design, cold storage buildings provide low interior temperatures that generally change very little over time. Therefore, in all but the coldest climates, the prevailing heat flow is from exterior to interior. In other words, the top of the roof assembly is generally warmer than the metal deck below – at least for most of the year. This causes a pronounced temperature gradient across the roof’s insulation layers.

Vapor drive within cold storage buildings is a bit more complicated. Exterior relative humidity is constantly changing but is generally higher than humidity set points in cold storage buildings. Because moisture moves from high water vapor pressure to low pressure, a prevailing vapor drive is established from exterior to interior – similar to the prevailing heat flow. Assuming the roof membrane prevents inward vapor drive, a water vapor gradient is established by the insulation itself. In other words, a gradient forms because warm air holds more moisture than cold air. The roof therefore experiences lower relative humidity towards the upper insulation layers (warmer temperatures) and higher relative humidity towards the lower insulation layers (cooler temperatures). Under proper roof design, this moisture gradient is established by the respective temperature extremes, not by vapor drive from interior and exterior spaces.

How Does it Work?

The most straightforward means for preventing condensation involve the Exterior Envelope System Method (The ASHRAE Handbook: Refrigeration, Chapter 23, 2018). This method achieves three fundamental objectives:

A vapor barrier installed above the insulation effectively prevents unwarranted vapor drive from the exterior environment. The roof membrane generally serves this purpose.

Insulation thickness is optimized to thermally buffer the cold storage interior from the warmer exterior. Insulation requirements generally increase with decreasing storage temperatures.

The metal deck, though perforated and imperfect, still partitions the interior space from the greater roof assembly, including the all-important insulation layers. The insulation is therefore semi-isolated from potential vapor drive originating from both exterior and interior environments. Essentially, the insulation layer has it’s own vapor gradient, safely shunting vapor within itself over the course of changing exterior temperatures.

What happens at high interior humidity?

Many storage facilities are maintained at high relative humidity (>70%). In those scenarios, a vapor gradient is established from interior to exterior. This vapor drive is typically mitigated by the roof deck or by an additional vapor barrier applied over the underlayment/deck. That which isn’t managed by the deck assembly (through perforations and seams) is subject to warming conditions found within upper portions of the insulation. As this air/vapor warms, its capacity to hold moisture also increases, lowering RH and preventing unwanted moisture accumulation. Though some conditions and climates may warrant additional vapor controls, these represent exceptions and not the norm.

What vapor does not move on its own, it needs air to move. As such, sealing the facility from air movement is the most important consideration when designing cold storage facilities roofing systems, they must be protected against vapor migration. Water vapor can’t move through the roof system to the cold building interior and condense if it never makes its way into the roofing system. Water condensation is where problems will arise. It is worth mentioning that air can move through the blocking and under gravel stops and copings, and force its way through the building components and into the building. A

Additional Considerations

The above discussion assumes that vapor moves solely by vapor diffusion. Unfortunately, this is not the case. Moisture transported by air leakage can have devastating effects to interior storage conditions as well as the roof assembly itself. Achieving an airtight enclosure is therefore paramount. Specific considerations involve proper air sealing of roof deck seams, deck penetrations, and adjacent parapet and wall connections.

Thermal bridging and insulation gaps create unwarranted heat loss and increased potentials for condensation. Insulation boards are therefore installed as two or more layers with offset joints. Upper insulation layers are typically adhered to the layer below to prevent thermal bridging and condensation at penetrated fasteners.

No two buildings are exactly alike. Therefore, cold storage roofs must be designed according to the unique demands posed by the required conditions. Space use, humidification, dehumidification, and nuances of air circulation can have profound impacts on assumed roof performance.

Authored by Jarrett Davis of MacMill Consulting.